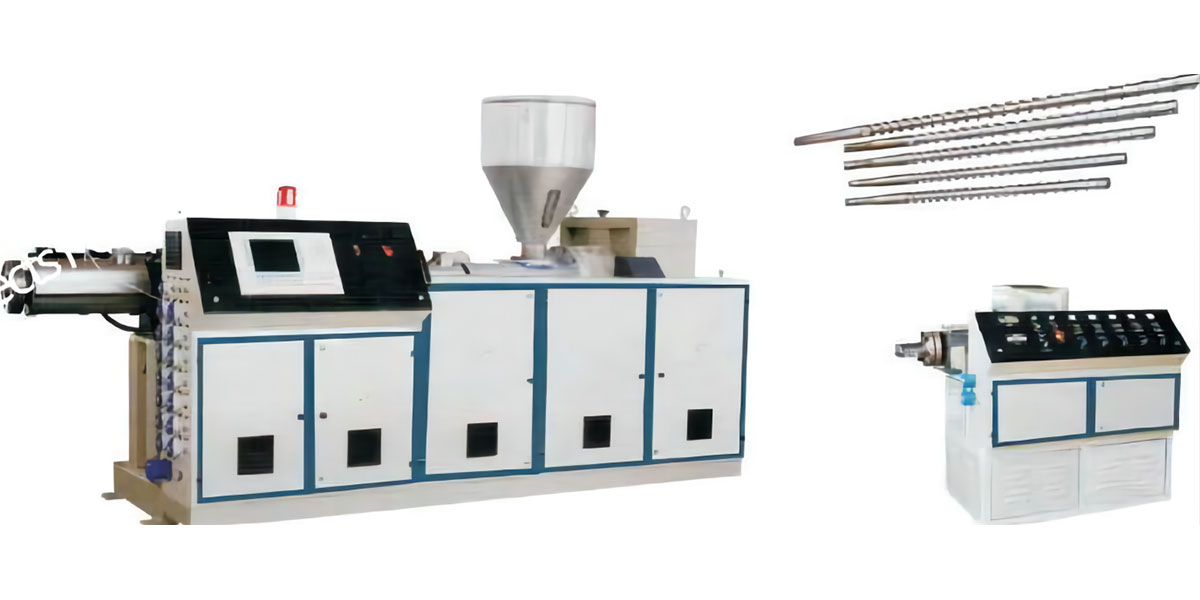

LSJZ series conical twin screw extruder

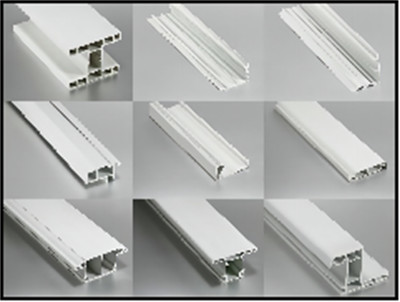

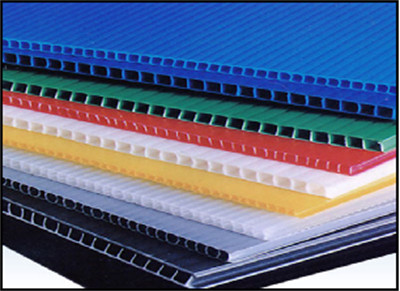

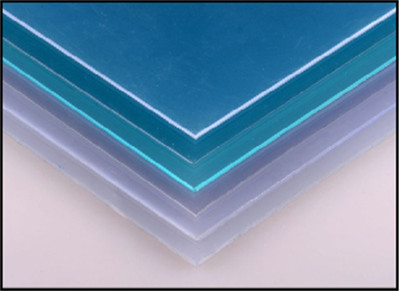

LSJZ series conical twin-screw extruder is a professional equipment suitable for all kinds of PVC powder and PVC wood-plastic extrusion. Equipped with different molds and auxiliary machines, it can produce various types of PVC sheets, plates, profiles and pipes. and hot-cut granulation.

The machine adopts cast aluminum heater ring for heating and air cooling system for cooling. It has the characteristics of fast and uniform heat transfer, convenient operation and maintenance, etc.

The screw core is made of alloy material to improve efficiency. According to different formulas of users, the most reasonable screw structure can be configured to achieve the best plasticizing state and logistics quality.

The reduction box and distribution box use imported bearings, oil seals in the mountain, and the gears are made of 38CrMoA1A alloy steel, which is nitrided.

Temperature control system temperature control table, imported contactor control, temperature control accuracy can reach 1C. The motor adopts AC motor, imported frequency conversion speed control or DC motor, British Continental 59. DC control. The electrical system has a number of fault alarm functions and a current protection device.

| Main techinical parameter: | |||||

|

Model |

LJSZ-51 |

LJSZ-55 |

LJSZ-65 |

LJSZ-80 |

LJSZ-92 |

|

Screw diameter(mm ) |

51/105 |

55/110 |

65/132 |

80/156 |

92/188 |

|

Effective working length of screw(mm) |

1050 | 1150 |

1440 |

1800 |

2500 |

|

Screw speed (r/min) |

1—32 |

1—32 |

1-34.4 |

1—38 |

1-32.9 |

|

Extruder motor |

18.5kw |

22kw |

37kw |

55kw/75kw |

110kw |

|

Heating power (kw) |

7.9 |

18 |

24 | 34 |

58 |

|

Out put(kg/h) |

150kg/h |

180kg/h |

250kg/h |

480kg/h |

800kg/h |

|

Center height (mm) |

1000 |

1000 |

1000 |

1100 |

1100 |

| Note: The abowe paramelers are subject change without nolice | |||||

LSJ Series single-screw extruder

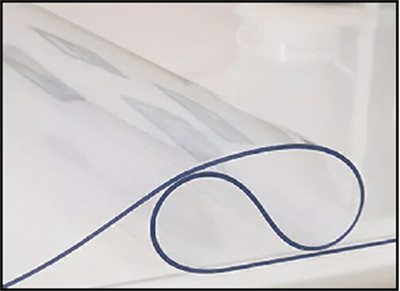

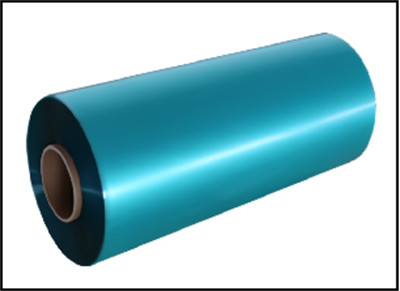

LSJ series single screw extruder is mainly composed of barrel screw, power transmission system, heating, cooling and electrical control, etc. It is mainly used for sheet, plate, film, Plasticizing and extrusion molding of profiles, pipes, and granulated plastic products.

| Main techinical parameter: | |||||||

|

Model |

LSJ30 |

LSJ65 |

...... |

LSJ90 | LSJ100 | LSJ120 | LSJ150 |

|

Screw diameter(mm ) |

30 |

65 |

...... |

||||

|

Diameter ratio (L/D) |

20-40 |

||||||

|

Main motor power (kw) |

5-7.5kw |

18-30kw |

...... |

37-75kw | 55-90kw | 90-132kw |

110- 160kw |

|

Barrel heating power(kw) |

4kw |

12kw |

...... |

30kw |

40kw |

45kw |

60kw |

|

Screw speed |

35-140rpm/min |

||||||

| Note: The abowe paramelers are subject change without nolice | |||||||

LSJP series counter-rotating parallel twin-screw extruder

LSJP counter-rotating parallel twin-screw extruder is a special equipment suitable for extrusion molding of various PVC powders. Equipped with different moulds and auxiliary machines, it can produce various PVC plastic pipes, profiles, plates, sheets, bars and pellets. The screw is cooled by an oil cooling system. Suitable for soft and hard PVC including C-PVC; Unique screw design to achieve high plasticization and high output of the product; More precise temperature control system; High torque gearbox to make the main engine run smoothly; The gearbox has automatic circulation Lubricating oil system; energy saving and easy maintenance

| Main techinical parameter: | |||||

|

Model |

LSJP75 |

LSJP85 |

LSJP90 | LSJP110 | LSJP120 |

|

Main motor power (kw) |

55-75kw | 90-132kw |

110-160kw |

110-160kw |

132-200kw |

|

Screw diameter(mm ) |

75 | 85 | 90 | 110 |

120 |

|

Screw speed |

45 | 45 | 45 | 38 |

30 |

|

Diameter ratio (L/D) |

25-40 |

||||

|

Maximum output (kg/h) |

300 |

450 |

650 | 850 | 1150 |

| Note: The abowe paramelers are subject change without nolice | |||||

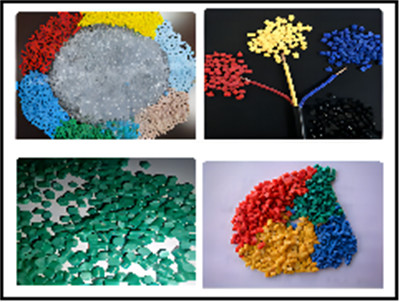

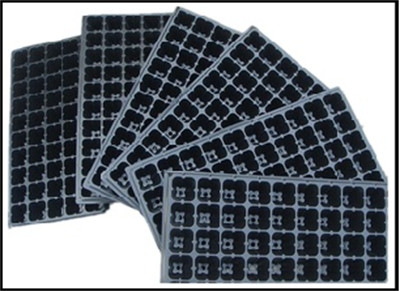

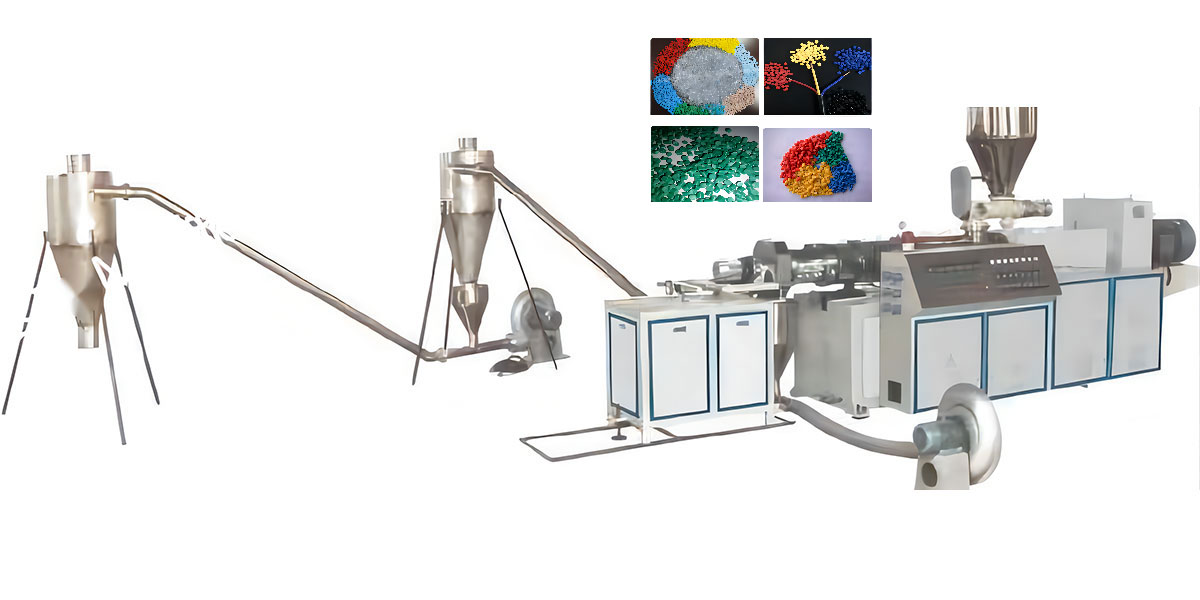

PVC Hot-cut Pelletizing Extrusion Line Equipment

Hot-cut pelletizing production equipment can produce rigid PVC pellets and cable pellets. The equipment can adopt the screen changing device according to the user's needs,

The production line adopts hot-cut material, air-cooled, and can adopt one-stage or multi-stage air-cooled conveying method according to the characteristics of the processed particles, and the length of the particles can be adjusted arbitrarily.

High prec ision pelletizing

High cutting efficiency

High production capacity

Installation easy to move

|

Model |

Screw specs (mm) |

Granule size (mm) |

Motor power(kw) |

Capacity(kg/h) |

|

LSJZ55 |

55/110 |

Φ3-5 |

22/30 |

100-120 |

|

LSJZ65 |

65/132 |

Φ3-5 |

37 |

220-260 |

|

LSJZ80 |

80/156 |

Φ3-5 |

55 |

320-450 |

|

LSJZ92 |

92/188 |

Φ3-5 |

110 |

650-800 |

| Note: The abowe paramelers are subject change without nolice | ||||

LRL-ZSeries hot and cold mixing unit

LRL--Z series plastic mixer is mainly suitable for mixing, drying, drying and drying of various resins such as polyethylene, polypropylene, polyvinyl chloride and other raw materials before processing, and can also be used for phenolic Resin mixing, the unit combines hot and cold mixing processes.

1. High-quality production process (welding and polishing), so that the material will not stick to the inside of the pot body wall and it is easy to discharge quickly and easily.

2. Sheli operation: stable, no noise, short time, fast mixing and so on.

LRL-W Series hot and cold mixing unit

LRL--W horizontal mixing unit is mainly used for mixing, stirring, drying, coloring and other processes of various materials in the litter, rubber, daily chemical industry and other industries. It is an ideal equipment for the production of plastic sheets, pipes, profiles and degradable plastics.

|

Model |

LRL-ZSeries hot and cold mixing unit |

LRL-W Series hot and cold mixing unit | ||||

|

Parameter |

LRI -200/500 |

LRI -300/600 |

LRI -500/1000 |

LRI -800/1600 |

LRL-800,/2000 |

LRL-1000/3000 |

|

Total volume |

200/500 |

300/600 |

500/1000 |

800/1600 |

800,/2000 |

1000/3000 |

| Effective capacity |

150/320 |

290/360 |

330/640 |

600/1050 |

600/1550 |

700/2100 |

|

Stirrinfl speed |

950/130 |

950/100 |

860/50 |

740/50 |

700/50 | 600/50 |

|

Mixing time |

8-2 |

8-12 |

8-15 |

8-15 |

8-12 |

8-12 |

| Motor power |

45&11 |

55&11 |

75&15 |

132/&22 |

132/30 | 160/30 |

|

Overall timension |

4580X2240X2470 |

4800X2640X2480 |

5600X3000X3100 |

5170X3200X4480 |

5170X3800X5380 |

5620X4200X5800 |

|

Weiht |

2500 |

3200 |

3800 |

5200 |

5500 |

6500 |

| Note: The abowe paramelers are subject change without nolice | ||||||

]]>

LWP Series Sheet, Board, Profile, Pipe Crusher

The shredder is a kind of solid waste mechanical environmental protection equipment, which is used to shred high-density polyethylene (HDPE) plastic products, stone plastic, foamed PVC profiles, pipes, plates, and various types of sheet recycling edge materials, which is conducive to plastic recycling and regeneration. Production of plastic pellets

The blade is made of high-quality tool steel, which is sharp in breaking and has a long service life. The blade mounting design is retractable and adjustable. The movable cutter seat is a stepped scissor design, which decomposes the cutting force and doubles the crushing force.

The material of the movable knife seat is flexible and reasonable, and it is not easy to break or wear. It is fastened with high-strength steel screws (grade 12.9), and the structure is solid and durable.

The main body is made of Q235A high-quality structural steel material for the rear wall, which can avoid long-term use of broken materials and affect the mechanical properties.

|

Model |

LWP400 |

LWP500 |

LWP600 |

LWP800 |

|

Power |

11 |

18.5 |

37 |

55 |

|

Crushing chamber |

380 |

450 |

550 |

680 |

|

Moving knife |

5 |

5 |

18 |

24 |

|

Fixed knife |

2 |

2 |

4 |

8 |

|

Yield |

250 |

350 |

450 |

550 |

| Screen hole diameter |

Φ6-12 |

Φ6-12 |

Φ6-12 |

Φ6-12 |

| Note: The abowe parameters are subject change without notice | ||||

LMP Series PVC, PE, PS, PA, PC Grinder

The pulverizer/grinder adopts a new tool structure, which overcomes the characteristics of low output and coarse particles, and is energy-saving and environmentally friendly. Wide range of application: PVC, PE, PS, PA, PC and other materials are ground into 20-80 mesh powder. .It is completely sealed during the grinding process, without dust pollution; the cooling system adopts the combination of air and water for cooling. Fully automatic continuous operation, closed design, using its own air volume and air pressure to collect the prepared powder without dust leakage. It is easy to install and maintain, and it can be cleaned by opening the door cover.

|

Model |

LMP-500 |

LMP-600 |

LMP-800 |

|

Powder chamber diameter |

Φ500mm |

Φ600mm |

Φ800mm |

|

Number of rotors |

Group 1 |

Group 1 |

Group 1 |

|

Spindle speed |

3700 |

3500 |

3200 |

|

Power |

37 |

55 |

75 |

|

Yield |

150-280 |

200-550 |

450-850 |

|

Fineness |

15-120 mesh |

15-120 mesh |

15-120 mesh |

|

Dimensions |

60001550x3000mm |

6100><1650x3200mm |

6600x1750x3400mm |